Road blockers are critical security devices used to control vehicle access to sensitive areas, enhance perimeter security, and prevent unauthorized vehicular entry. They are commonly used in high-security locations such as government buildings, military installations, embassies, airports, and commercial complexes. If you are considering purchasing road blockers, here are key aspects you need to understand:

1. Types of Road Blockers

There are several types of road blockers available, each designed for specific applications and security levels:

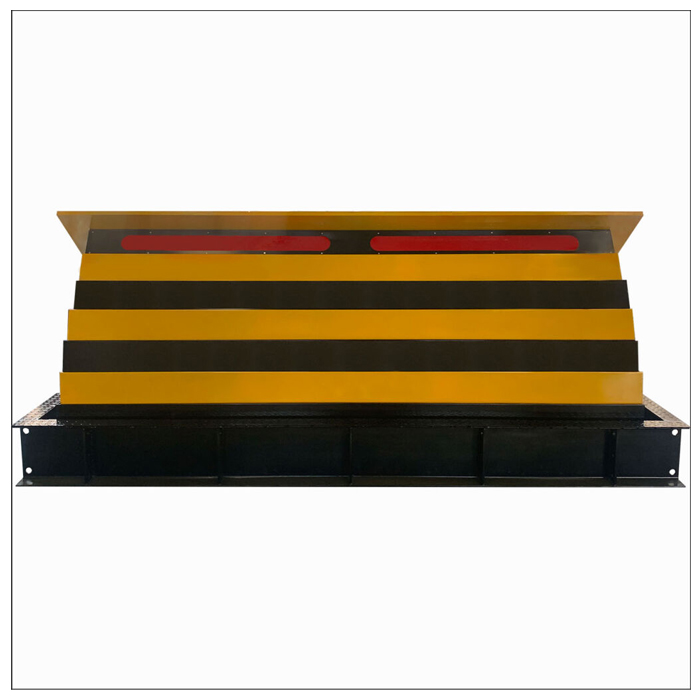

Hydraulic Road Blockers: Operate using hydraulic systems, offering high impact resistance and durability. They are suitable for high-security applications.

Pneumatic Road Blockers: Use air pressure for operation. They are faster and quieter than hydraulic models but may require more maintenance.

Electro-Mechanical Road Blockers: Use electric motors and mechanical systems. They offer a balance between speed and impact resistance.

Manual Road Blockers: Operated manually, ideal for locations where electricity or hydraulic systems are not feasible.

2. Impact Resistance and Security Level

The primary purpose of road blockers is to stop unauthorized vehicles. Therefore, their impact resistance is crucial:

Crash Ratings: Look for blockers with internationally recognized crash ratings such as ASTM, IWA, or PAS 68, which indicate their ability to withstand vehicle impacts.

Vehicle Stopping Power: Ensure the blocker can stop vehicles of different sizes and speeds. Higher-rated blockers can stop heavier and faster-moving vehicles.

3. Operational Speed

The speed at which the road blocker can deploy and retract is important for ensuring timely security responses:

Rising Time: Consider how quickly the blocker can rise to full height from a lowered position.

Lowering Time: Evaluate the time it takes to lower the blocker to allow authorized vehicles to pass.

Emergency Fast Operation: Some models have emergency features that enable rapid deployment in critical situations.

4. Durability and Maintenance

Road blockers must withstand harsh environmental conditions and frequent use:

Material and Construction: Opt for road blockers made from high-strength materials like reinforced steel or alloy. Ensure they are corrosion-resistant, especially if installed outdoors.

Maintenance Requirements: Assess the ease of maintenance and availability of spare parts. Regular maintenance is essential to ensure long-term functionality.

5. Installation and Power Requirements

Proper installation is crucial for the effective operation of road blockers:

Installation Complexity: Some road blockers require extensive groundwork and civil works, while others are surface-mounted for easier installation.

Power Supply: Ensure a reliable power source for hydraulic, pneumatic, or electro-mechanical road blockers. Consider backup power options like generators or battery systems for uninterrupted operation.

6. Safety Features

Safety is a paramount consideration in road blocker systems:

Safety Sensors: Look for road blockers equipped with sensors to detect vehicles and pedestrians, preventing accidental injuries or damage.

Emergency Manual Override: Ensure the system has a manual override option for emergency situations or power failures.

Signage and Lighting: Proper signage and lighting enhance visibility and awareness for drivers and pedestrians.

7. Integration with Security Systems

Road blockers should seamlessly integrate with existing security infrastructure:

Access Control Systems: Ensure compatibility with access control systems like RFID, biometric scanners, or keypad entry.

Alarm Systems: Integration with alarm and surveillance systems enhances overall security monitoring and response capabilities.

Remote Control: Some road blockers offer remote control options, allowing security personnel to operate them from a central control room.

8. Cost Considerations

Budget is always a key factor in purchasing decisions:

Initial Cost: Compare the initial purchase price of different models and brands. Higher upfront costs may be justified by better performance and lower maintenance requirements.

Operational Costs: Consider the long-term operational costs, including energy consumption, maintenance, and repairs.

Warranty and Support: Look for manufacturers that offer comprehensive warranties and reliable customer support.

Conclusion

Purchasing road blockers is a significant investment in security infrastructure. By understanding the various types, impact resistance, operational speed, durability, safety features, installation requirements, integration capabilities, and cost considerations, you can make an informed decision that meets your security needs and budget constraints. Prioritize quality and reliability to ensure that your road blockers provide effective and long-lasting protection for your facility.